Zirconia nozzle refractory insert for tundish nozzle

Model Number: hongtai

Certification:

Minimum Order Quantity:

Ladle nozzle

zirconia nozzle tundish

|

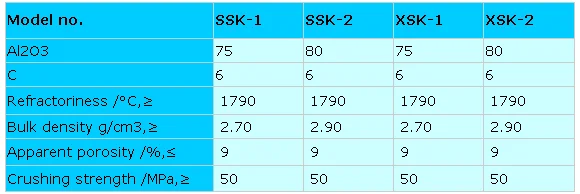

tem |

Index |

||

|

Zirconium core |

Coat |

||

|

XF-94Z |

XF-95Z |

WG-65 |

|

|

ZrO2 ≥ |

94 |

95 |

- |

|

Al2O3 + C ≥ |

0 |

0 |

65 |

|

Apparent porosity % ≤ |

8 |

7 |

12 |

|

Bulk density g/cm3 ≥ |

4.5 |

5.4 |

2.8 |

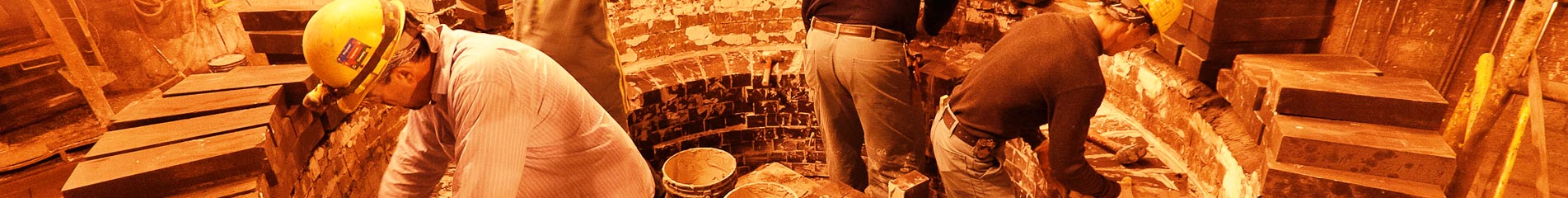

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..